Fabric

Fabric Pioneering "micro-fulfillment" company Fabric, which has been something of a darling among investors, just passed an important milestone with a valuation that exceeds a billion dollars. The company uses robots and geographically strategic fulfillment centers to get products to customers in a hurry, as quickly as one-hour after an e-commerce order is made.

Is the company the future of fulfillment in a world that previously has been dominated by Amazon? Investors certainly seem to think so. The company has netted a whopping$336 million in total funding on the promise of democratizing fast fulfillment.

The reason for the investor enthusiasm is readily apparent. This year saw e-commerce sales penetration more than double to 35%, fueled by the COVID-19 pandemic's acceleration of existing online shopping trends. The same-day delivery market in the US is poised to grow by $9.82 billion over the next four years. Meanwhile, supply chain catastrophes and strained fulfillment capacity has created a bottleneck. Fabric thinks it can solve the problem with a fully integrated micro-fulfillment process powered by AI and robots.

"At the center of this perfect storm of e-commerce is Fabric and our ability to enable on-demand retail at profitable unit economics," says Elram Goren, Fabric CEO and co-founder. "We see this milestone as a real turning point in the industry, from what was once intrepid exploration of micro-fulfillment to total market validation and now rapid expansion."

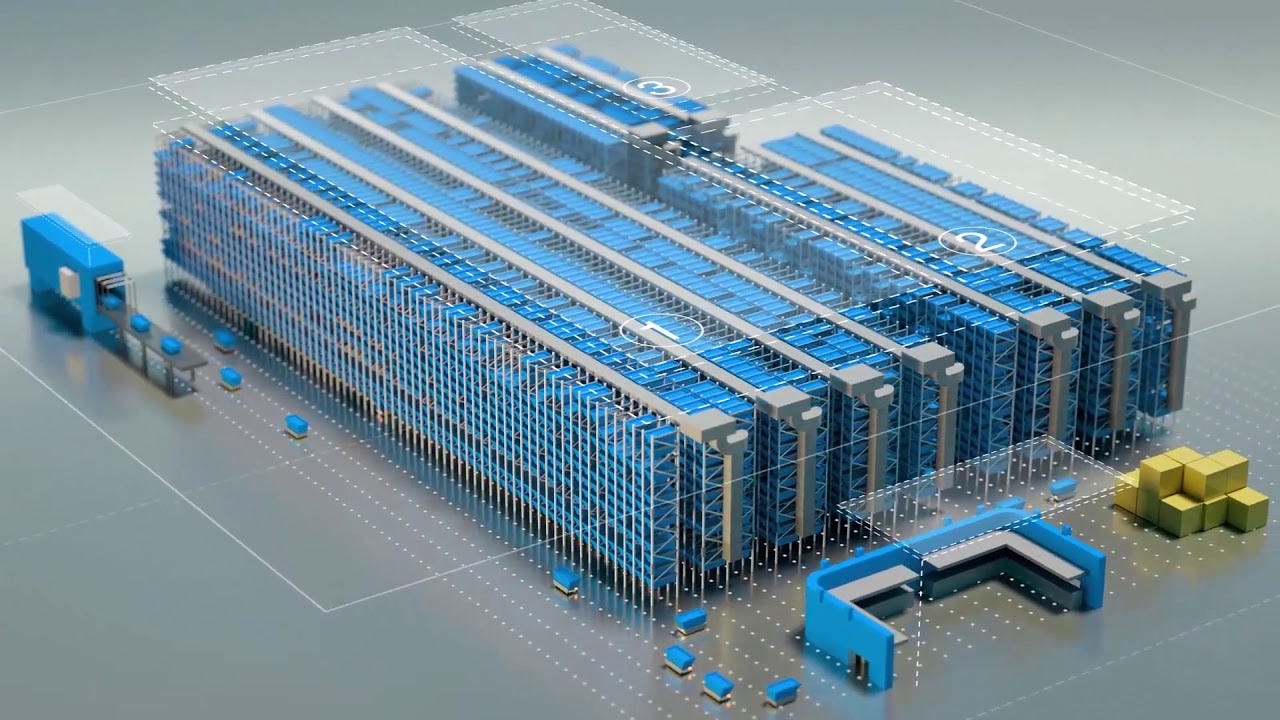

The recipe to democratize the last-mile logistics sector, according to Fabric, is a blend of high tech fulfillment robots and smaller-than-average fulfillment centers located in urban zones close to customers. The idea is that the physical remoteness of typical logistics facilities prevents most retailers from offering true on-demand delivery outside select major metropolitan markets. But by harnessing networks of tiny automated hubs, micro-fulfillment could enable retailers to store their goods in the hearts of cities while still benefiting from the efficiency of automation.

A couple of years ago, Fabric (then CommonSense Robotics) proved the concept with its first 1-hour fulfillment delivery, which is made in partnership with Super-Pharm, an Israeli health and beauty retailer. Fabric runs micro-fulfillment operations for grocery and general merchandise retailers in New York City, Washington, DC, and Tel Aviv. The company recently announced major partnerships with Walmart, Instacart, and FreshDirect.

It's no surprise that all of those companies are competitors of the many-headed Bezos hydra. There seems to be a fully dawned recognition within the retail space that Amazon's shrewd move to corner the logistics market can't be replicated or challenged by any one retailer. Smaller enterprises have a unique opportunity to create their own logistics operations and compete on customization and customer experience, which is what startup PetFriendly has done. But players like Walmart, which aren't capable of competing on customization, need massive fulfillment technology infrastructure, and it's far more attractive to team up with a technology-focused service provider than it is to create that infrastructure from scratch, a risky bet.

Investors have responded favorably to Fabric's position in the marketplace. The latest$200 million Series C funding round was led by existing investor Temasek, with participation from Koch Disruptive Technologies, Union Tech Ventures, Harel Insurance & Finance, Pontifax Global Food and Agriculture Technology Fund (Pontifax AgTech), Canada Pension Plan Investment Board (CPP Investments), KSH Capital, Princeville Capital, Wharton Equity Ventures, and others.

"We believe the movement to local fulfillment presents an opportunity to make retail and e-commerce more sustainable, and we're thrilled to partner with the leader in micro-fulfillment to make this vision a reality," says Eric Kosmowski, Managing Partner at the Princeville Climate Technology Fund. "By leveraging existing real estate with a small footprint in close proximity to end consumers, utilizing more sustainable packing materials, and minimizing shrink and waste through smart inventory management, Fabric's micro-fulfillment centers could lower last-mile emissions significantly."

Tags chauds:

Innovation et Innovation

robotique

Tags chauds:

Innovation et Innovation

robotique